Sullivan Mine Case Study

Heavy excavator on a quarry. Excavation machinery. Earthmover

Background

Sullivan Mine is located in SE British Columbia in Kimberley City. It was the world’s largest lead-zinc mine from 1917 to 2001 until it was closed by the owner, Teck Cominco, on December 21, 2001. As with most brownfield sites that contain mining activity, there is a continuous Teck Cominco presence onsite, maintaining the de-watering system that collects and pumps acid-drainage water from the mine tailings and operations. The underground mine dewatering system collects contaminated water and sends it for treatment and final discharge into the St. Mary River.

Figure 1 Incident site showing the test collection shed.

Incident Timeline

Monday – May 15, 2006: Pryzm Environmental employee Doug Erickson entered the #1 Shaft Waste Rock Dump monitoring building to perform routine water monitoring activities.

Wednesday – May 17, 2006: Mr. Erickson was reported missing to Kimberley Operations by his wife. Bob Newcombe, Senior Construction Coordinator for TCML, discovered Mr. Erickson unconscious and slumped over the water sampling weir in the monitoring building. Mr. Newcombe called 911 (emergency services) and informed the dispatcher that he would attempt to reach Mr. Erickson. Emergency Health Services (911) arrived, and Paramedic Kim Weitzel descended into the weir to respond to what she believed was an employee drowning. After several attempts to contact Ms. Weitzel, the second attendant, Shawn Currier, followed to check on her status inside the sampling shed. Onsite personnel called 911 (emergency services) to bring additional resources. The dispatcher was informed that there were now four victims, and gas was suspected.

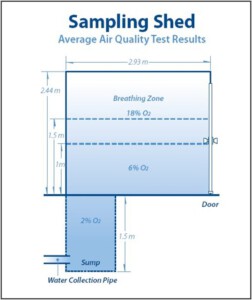

Additional Fire and Rescue crews were dispatched and arrived on the scene. The Fire and Rescue crew’s initial response team requested a Confined Space Response Team and equipment. Tests were conducted for Hydrogen Sulfide, Oxygen, Carbon Monoxide, and Lower Explosive Limit. Ongoing testing determined that the atmosphere inside the shed was oxygen-deficient and that the oxygen-deficient atmosphere entered the shed through a drainage pipe installed to direct water from the collection ditch to a treatment facility.

Figure 2 Sampling Shed Testing Results

Lessons Learned

- There were established protocols and procedures for workers operating in this environment, but the call-in procedures were not followed.

- The site did not have a formal process for ingress and egress from the site. There was no way to identify how many workers or contractors were on site at any given point. This lack of Situational Awareness meant that two workers were onsite alone with no established mechanism to establish a distress call or communicate an issue to an external third party.

- The paramedics did not conduct a thorough risk and hazard assessment before entry into the sampling shed. They accepted the initial information that someone had drowned. In the U.S. this may have been mitigated because of the requirement for Fire and EMS to be dispatched together. Although the remote location of the incident may have contributed to a lack of available resources to respond initially.

- This incident showed us that standard work that is repetitive and benign can be fatal; failure to follow standard procedure can allow for potentially fatal situations to occur.

- Just because a mining site is non-operational and closed does not make it safer. The hazards are more subtle and require a greater focus on thorough consequence management and continual assessment of hazards before executing any work.

Mitigations

- All sampling locations will be signed as follows: “Danger possible oxygen deficient atmosphere.” All such locations are to be locked with single-key access.

- No person shall enter any sampling enclosure located downstream of the mine waste dump without being equipped with and trained in the use of oxygen monitoring equipment and no person shall enter sampling enclosures located downstream of mine waste dumps without testing air quality and determining it is safe before entry. All enclosed sampling stations are to be equipped with a positive ventilation system, with a maximum air exchange time of 10 minutes.

- Maintain a current site roster to monitor employees’ and contractors’ locations while on site.

- No employee or contractor should be working alone.

- Develop and implement an assessment program to determine how the environment became oxygen-depleted, to prevent a reoccurrence of this incident.

What should we take away from this tragedy? Several key learnings need to be considered by all companies regardless of the sector they are in. All workplaces need a comprehensive risk and threat assessment to identify hazards that may/will impact their employees. This assessment should drive every effort to incorporate safety engineering into the design of employee workspaces. In the case of the Sullivan Mine, Identifying the hazard of potential low oxygen environments could have led to engineering solutions, including ventilation of the sample shed, monitoring and alarming for low oxygen conditions in the sampling shed, access control (locks, gates, warning labeling) to the building, and a modified sampling procedure that minimized the exposure risk to the employee.

Additionally, developing a comprehensive response plan and crisis communications plan that can identify the specific actions to be taken in the case of a missing or deceased worker can minimize response times and allow for consistent and mindful decision making in a time of trauma and crisis.